The titanium-coated cementless femoral stem is an implant used in reconstructive hip replacement surgery. As a Titanium Coated Femoral Stem, it is made of medical-grade alloy and coated with titanium to promote bone ongrowth and achieve secure fixation without cement. Its tapered design closely matches the anatomy of the proximal femur, allowing the stem to fit firmly into the medullary canal during a Hip replacement implant procedure.

This femoral stem is typically used in primary hip arthroplasty where a cementless, press-fit fixation method is preferred. To complete a total hip construct, it can be paired with various acetabular cups and femoral heads. Its geometry, surface treatment, and size range are selected by orthopedic surgeons to ensure predictable and reproducible outcomes in standard cementless hip replacement operations.

Titanium-coated surface – Provides a roughened surface for bone ongrowth and long-term fixation.

Cementless press-fit design – Achieves secure fixation through anatomical shaping and radial compression.

Tapered shank structure – Matches the natural contour of the proximal femur for stable fitting.

Medical-grade alloy – Strong, corrosion-resistant, and durable.

Wide size range – Supports various anatomical needs of hip arthroplasty.

Controlled surface texture – Ensures consistent tactile properties across implants.

High-precision manufacturing – Maintains tight tolerances and stable performance.

This femoral stem is used when cementless fixation is required during hip arthroplasty. Common scenarios include:

Primary cementless hip reconstruction

Degenerative hip disease requiring stable femoral fixation

Cases requiring a Titanium Coated Femoral Stem for biological ongrowth

Total hip replacement requiring compatibility with acetabular cups and femoral heads

(This information describes typical clinical usage and does not constitute medical advice.)

Specification

| Brand | JinMing Medical |

|---|---|

| Material | Medical-grade stainless steel / Medical-grade titanium alloy |

| Locking hole design | Variable angle locking holes (±15° range) |

| Plate design | Left / right symmetrical design, conforming to the anatomy of the proximal tibia |

| Screw diameter | 3.5mm cortical screws, 3.5mm locking head screws |

| Number of holes selection | 7-15 holes option |

| Surface treatment | Titanium anodizing / Nickel-chromium polishing |

| System compatibility | Fully compatible with Bone Fixation System and Orthopedic Implant |

Why Choose JinMing Medical?

Global Trust: A trusted partner to medical professionals in over 60 countries.

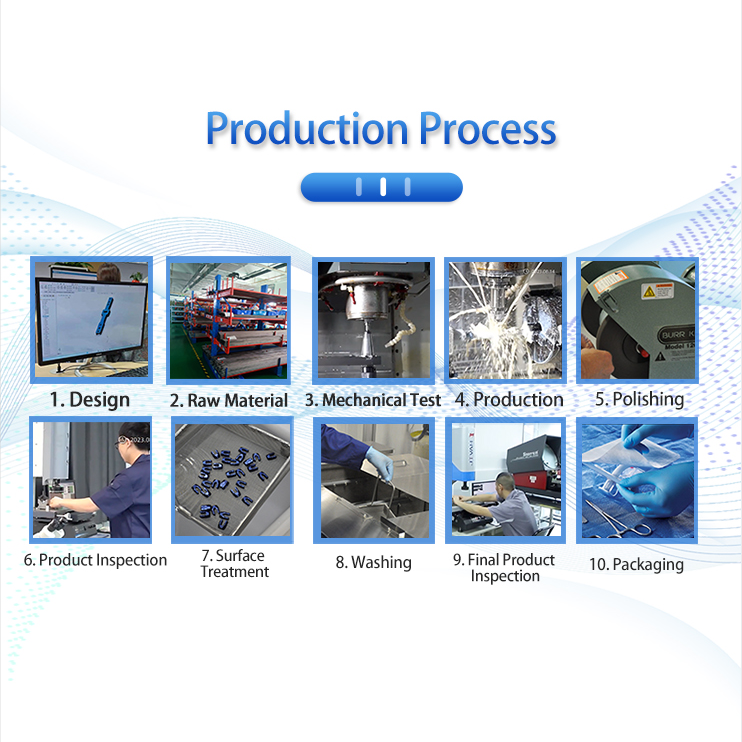

Expertise & Precision: Over 20 years of experience in orthopedic implants and instruments, utilizing 5-axis CNC and ZEISS CMM for ±0.01 mm accuracy.

Rigorous Quality: Committed to rigorous testing and international medical standards.

Customized Support: Comprehensive OEM/ODM services, backed by fast delivery and dedicated after-sales support.

Certifications & Quality Assurance

Internationally Certified: All products comply with CE and ISO13485 international quality standards.

100% Quality Inspected: Every product is fully inspected to ensure safety and performance.

Full Customization: We offer OEM/ODM services for screw angles, plate sizes, and labels to meet your specific needs.

Your Trusted Partner: We are committed to being your reliable partner in orthopedic innovation.